Fillet welding refers to the process of joining two pieces of metal together when they are perpendicular or at an angle. These welds are commonly referred to as tee joints, which are two pieces of metal perpendicular to each other, or lap joints, which are two pieces of metal that overlap and are welded at the edges. The weld is triangular in shape and may have a concave, flat or convex surface depending on the welder’s technique. Welders use fillet welds when connecting flanges to pipes and welding cross sections of infrastructure, and when bolts aren't strong enough and will wear off easily.[1]

There are two main types of fillet weld: traverse fillet weld and parallel fillet weld.

Measure Weld Throat

Aspects[edit]

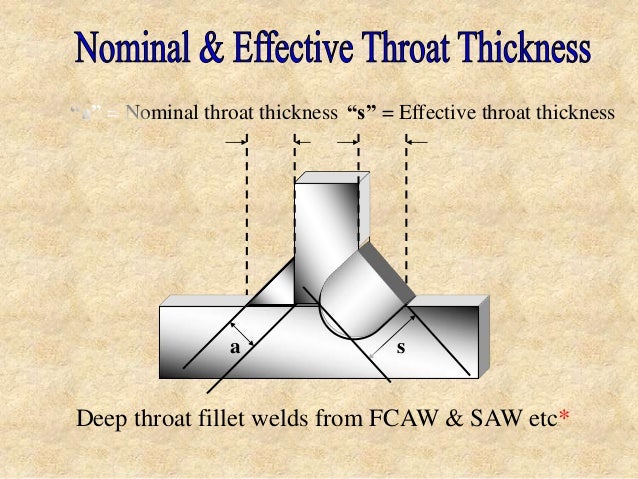

There are 5 pieces to each fillet weld known as the root, toe, face, leg and throat.[2] The root of the weld is the part of deepest penetration which is the opposite angle of the hypotenuse. The toes of the weld are essentially the edges or the points of the hypotenuse. The face of the weld is the outer visual or hypotenuse that you see when looking at a fillet weld. The legs are the other two sides of the triangular fillet weld. The leg length is usually designated as the size of the weld. The throat of the weld is the distance from the center of the face to the root of the weld. Typically the depth of the throat should be at least as thick as the thickness of metal you are welding.[1]

Thus far, I have been unable to easily calculate the minimum effective throat of a flare-bevel with reinforcing fillet due to the complex geometry of the weld throat. The best method I have found so far is to draw it in AutoCAD to scale and figure it out from there, but this is relatively time-consuming. 1) an equal leg fillet weld in a 90 degree joint the width of the face is 2 times that of the throat. So if you can only measure the face AND the leg sizes are equal you can approximate the throat. 2) If you can only measure the smallest leg, the throat will be.707 times that dimension. 3) You can only use a throat gage on a flat or concave weld. Weld design Throat area of fillet weld A mm 2, in 2 for full weld length for load-bearing (active). Flange thickness mm, in Parent topic: Welding Joints. Theoretical Throat Concave Fillet Weld Size of Weld. = 1.4 tn or the thickness of the hub, whichever is smaller, but not less than 1/8 in.

Notation[edit]

Fillet welding notation is important to recognize when reading technical drawings. The use of this notation tells the welder exactly what is expected from the fabricator. The symbol for a fillet weld is in the shape of a triangle. This triangle will lie either below a flat line or above it with an arrow coming off of the flat line pointing to a joint. The flat line is called 'reference line'. The side on which the triangle symbol is placed is important because it gives an indication on which side of the joint is to be intersected by the weld. It is recognized that there are two different approaches in the global market to designate the arrow side and other side on drawings; a description of the two approaches is contained in International Standard ISO 2553, they are called 'A-System' (which is more commonly used in Europe) and 'B-System' (which is basically the ANSI/AWS system used in the US). In 'A-System' two parallel lines are used as reference line: one is a continuous line, the other is a dashed line. In the 'B-System', there is only one reference line, which is a continuous line. If there is a single reference line (B-System) and the triangle is positioned below the line, then the weld is going to be on the arrow side. If there is a single reference line ('B-System') and the triangle is positioned above the line, then the weld is going to be on the opposite side of the arrow.[3] When you find an arrow pointing to a joint with two triangles, one sitting below and one sitting above the line even with each other, then there is intended to be a fillet weld on the arrow side of the joint as well as the opposite side of the joint.[4] If the weld is to be continuous around a piece of metal such as a pipe or square, then a small circle will be around the point where the flat line and arrow pointing to the joint are connected.[5] Manufacturers also include the strength that the weld must be. This is indicated by a letter and number combination just before the flat line. Examples of this are 'E70' meaning the arcelectrode must have a tensile strength of 70,000 pounds-force per square inch (480,000 kPa; 4,900 kgf/cm2). There are also symbols that describe the aesthetics of the weld. A gentle curve pointing away from the hypotenuse means a concave weld is required, a straight line parallel with the hypotenuse calls for a flat faced weld, and a gentle curve towards the hypotenuse calls for a convex weld. The surface of the weld can be manipulated either by welding technique or by use of machining or grinding tools after the weld is completed. When reading a manufacturers technical drawings, you might also come across weld dimensions. The weld can be sized in many different ways such as the length of the weld, the measurements of the legs of the weld, and the spaces between welds. Along with a triangle, there will usually be a size for the weld for example (1⁄8”x3⁄8”) to the left of the triangle. This means that the vertical leg of the weld is to be 1⁄8” whereas the horizontal leg is to 3⁄8”. To the right of the triangle, there will be a measurement of exactly how long the weld is supposed to be.[6]If the measurements of the drawing are in mm the welds are likewise measured in mm. For example, the weld would be 3 x 10, the mm being understood automatically.

Intermittent fillet welds[edit]

An intermittent fillet weld is one that is not continuous across a joint. These welds are portrayed as a set of two numbers to the right of the triangle instead of just one. The first number as mentioned earlier refers to the length of the weld. The second number, separated from the first by a “-”, refers to the pitch. The pitch is a measurement from midpoint to midpoint of the intermittent welds. Intermittent welding is used when either a continuous weld is not necessary, or when a continuous weld threatens the joint by warping. In some cases intermittent welds are staggered on both sides of the joint. In this case, the notation of the two triangles aren't directly on top of each other. Instead, the side of the joint to receive the first weld will have a triangle further to the left than the following side’s triangle notation. As an end result of alternating intermittent fillet welds at each side, the space between welds on one side of the joint will be the midpoint of the opposite side’s weld.[7]

See also[edit]

Notes[edit]

- ^ abAlthouse p.185

- ^Hultenius p.3

- ^ISO 2553:2013

- ^Althouse p.186-190

- ^Haque, pages 2-6

- ^Haque, p. 4

- ^Althouse p.189

References[edit]

- Hultenius, D. (2008). Lecture 14 – Welded Connections.

- Weman, Klas (2003). Welding processes handbook. New York, NY: CRC Press LLC. ISBN0-8493-1773-8

- ISO 2553:2013, Welding and allied processes - Symbolic representation on drawings - Welded joints

- Cary, Howard B; Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. ISBN0-13-113029-3.

- Haque, M. E. (2010). Weld connections. Informally published manuscript, Department of Construction Science, Texas A&M University, College Station, Retrieved from http://faculty.arch.tamu.edu/mhaque/cosc421/Weld.pdf.

- Althouse, A. D. (1997). Modern welding. Tinley Park, Ill: Goodheart-Willcox. ISBN978-1-60525-795-2

This article provides notes on welding gauge.

After welding the welds are inspected for size and shape by means of welding gauges. These are metal plates or high gauge-sheets with cuts corresponding to the cross-section of a given size and type of weld.

Another gauge, simple in design, is shown in Fig. to measure the throat thickness of a fillet weld. The throat thickness readings are shown on the curving line of the gauge. The gauge is held as shown in the figure until a point of curve in the gauges touches the centre of the face of the weld and the curve of the gauge also rests against two sides making the Tee-joint.

Read Also: 7 Most Common Defects In Welding and its causes

At B, throat thickness of the fillet weld is 5-6 mm which is a point on the gauge touching the centre of the face of the weld.

On each gauge numerals are punched indicating the thickness of the work in millimeters for butt welds, and the leg in millimeters for fillet welds. As such, it is difficult to keep the size of a weld within accurate limits—each gauge has cuts for the maximum and minimum size of a given weld. A set of gauges for the most commonly used weld sizes (6-14 mm) is clamped by a ring or a bolt (Fig. ).

Read Also: Brazing vs Welding- Difference Between Brazing and Welding

Types of Welding gauges :

- Welding Inspection Ruler WG 01

- Universal welding gauge WG 2

- Welding gauge WG3

- Digital welding gage WG3 Digital

- HI-LO Welding Gage (WG4)

- Economy Single Purpose Hi-Lo Welding Gage

- Welding gage WG5

- Automatic Weld Size Weld Gauge WG7

- Bridge Cam Gage

- Adjustable Fillet Weld Gage WG8

- Pipe Pit Gage WG10

- Skew-T Fillet Weld Gauge WG12

- “V-WAC” Single Weld Gage

- Pocket Bridge Cam Gauge

Weld Throat Thickness Calculation Chart

Related posts: