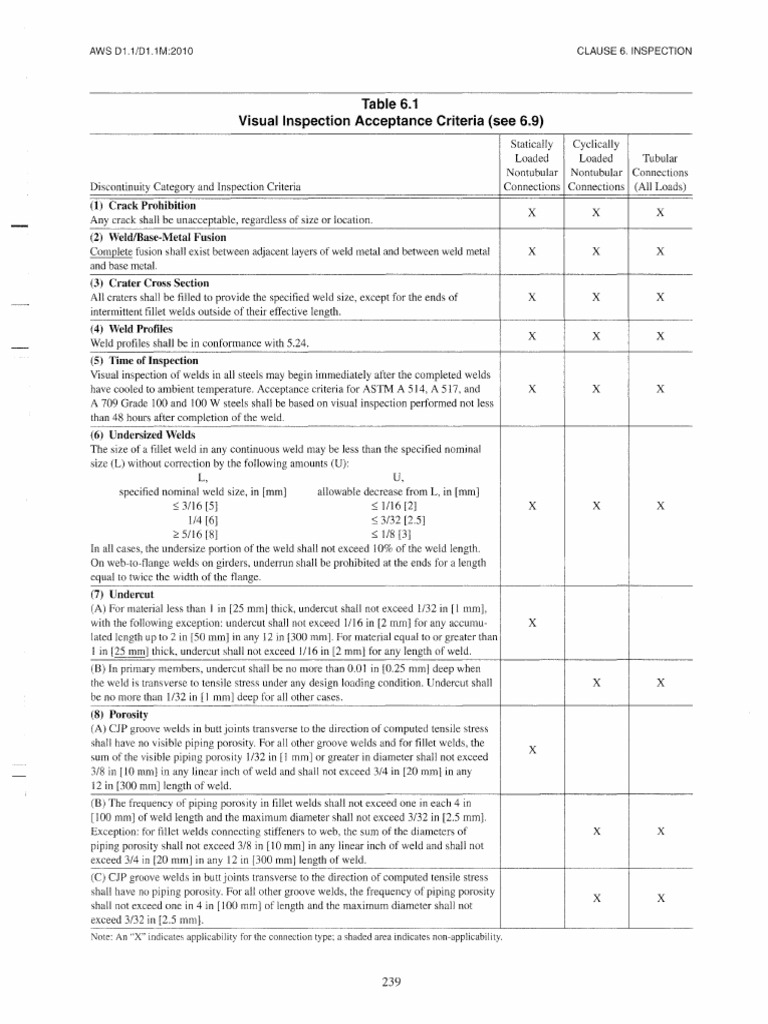

Liquid penetrant testing acceptance criteria depend on theconstruction code. For example, if a pressure vessel such as a reactor, heatexchanger, drum, process tower subjected to the test, then acceptance criteriacan be found in the ASME Code SectionVIII Div. 1 Appendix 8. If you are doing a penetrant test on steel structure,then you should look for acceptance criteria in the AWS D1.1

- Aws D1 1 Visual Inspection Acceptance Criteria Sample

- Aws D1.1 Visual Acceptance Criteria

- Aws D1 1 Visual Inspection Acceptance Criteria Checklist

- Aws D1 1 Visual Inspection Acceptance Criteria Template

Liquid Penetrant Testing Acceptance Criteria Based on ASMEVIII Div 1 Appendix 8

The ASME Code Section VIII Div. 1 Mandatory Appendix 8covers the acceptance criteria for Penetrant testing on the weld. Please noteAPI codes for rotating equipment also refer to this code. For instance, if youare performing a liquid penetrant testing on pipe weld to pump casing and youfind an indication, then you need to refer to appendix 8 of the code mentioned above for evaluationsince the API 610 does not directly address the acceptance criteria issue.

Video about welding inspection education It covers topics below welding defects covered in AWS D1.1 acceptance criteria for the welding defects porosity this. 1.3 This procedure may also be applied to the requirements set forth in AWS D1.1 structural weld inspection for both tubular and non-tubular inspection as well as API 6A requirements.

As per appendix 8, any indication greater than 1/16 in (1.5mm) shall be considered a relevant indication. You may ignore any indicationthat might be less than this value. It divides the indication into two groupsas follows:

Rounded indications: any relevant indication (it means if itsmajor dimension is greater than 1/16 (1.5 mm) ) shall be considered rejected ifit is greater than 3/16 in (5 mm)

Linear or elongated indication: all elongated indication arerejected regardless of the size. An indication is elongated or linear when itslength is three times of its wide.

As you see, there is more leeway for rounded indication.However, if several rounded indications existed in line and separated by ashort distance, might be considered rejected indications.

Liquid Penetrant Testing Acceptance Criteria for ProcessPiping - ASME B31.3

The acceptance criteria exactly is as the same of ASMESection VIII Div. 1 Appendix 8. The criteria addressed in clause number 344.4.2- Acceptance Criteria

Liquid Penetrant Testing Acceptance Criteria for Casting Usedfor Pressure Vessels and Rotating Equipment

The ASME Code Section VIII Div. 1 Appendix 7 addresses thisissue. The code requires all cracks and hot tears to be rejectedregardless of the size. The rounded indication can be considered rejected ifthe size is greater than 3/16 inch or 5 mm.

The linear indication depends on the thickness if the thickness is lessthan 0.75 inch then any linear indication greater than 1/4 inch will beconsidered unacceptable. If the thickness of the test object is between 0.75and 2.25 inch, then max allowed linear indication is the 1/3 of the thickness.

Aws D1 1 Visual Inspection Acceptance Criteria Sample

An indication mightbe rejected based on one code or standard and might be acceptable based anothercode and standard.

Aws D1.1 Visual Acceptance Criteria

The test evaluation and interpretation shall be done byqualified ASNT Level II or Level III liquid penetrant test technicians.

Return to Inspection 4 Industry Home

Aws D1 1 Visual Inspection Acceptance Criteria Checklist

Did you find this article useful? Click on below Like and G+1 buttons!

Aws D1 1 Visual Inspection Acceptance Criteria Template

New! Comments

Have your say about what you just read! Leave me a comment in the box below.